The Backlog Crisis in U.S. Government O&M Programs

Bruce Barron

TRM Marketing | GTM Management | Brand Management | Sales and Business Development Total Resource Management (TRM), Inc.

January 2, 2026

Section 1: What Is the Problem?

Backlogs in operations and maintenance (O&M) programs are a growing concern across U.S. federal agencies. These backlogs represent deferred maintenance tasks, repairs, and upgrades that have not been completed due to budget constraints, workforce limitations, or inefficient processes. While they may initially appear as a list of postponed activities that will eventually be addressed, backlogs represent a growing liability that often exists perpetually. The consequences of these delays are far-reaching, increasing costs over time, impacting asset reliability, safety, and diminishing mission readiness.

According to the U.S. Government Accountability Office (GAO), the federal deferred maintenance and repair backlog reached $370 billion in 2024. This staggering figure includes a wide range of assets such as:

- Federal buildings and facilities (e.g., courthouses, administrative offices)

- Military infrastructure (e.g., bases, depots, training centers)

- Transportation assets (e.g., roads, bridges, airfields)

- Utility systems (e.g., water, HVAC, electrical)

- Fleet and equipment (e.g., vehicles, machinery)

These assets are critical to the daily functioning of federal agencies and the services they provide to the public. When maintenance is deferred, it often leads to increased risk of emergency failures, higher lifecycle costs, reduced asset performance and reliability, lower staff productivity, and create difficulties in justifying future budgets.

For asset management teams, backlogs are a huge red flag. They signal inefficiencies in planning, resource allocation, and execution. More importantly, they represent risks that are unaccounted for. The longer a task is deferred, the more likely it is to escalate into a costly emergency repair or a safety hazard, and often needed parts can become increasingly unavailable or challenging to acquire.

Ignoring backlogs often leads to emergency failures that disrupt operations, safety hazards for staff and the public; budget overruns due to reactive repairs, and loss of trust from oversight bodies and stakeholders. Finding ways to proactively manage maintenance programs and reduce the risks associated with deferred work is a critical need in today’s environment.

Section 2: What Causes Backlogs?

Backlogs don’t appear overnight. They are the result of systemic issues that are compounded over time. In federal O&M programs, several root causes contribute to the accumulation of deferred maintenance:

1. Shrinking Budgets and Workforce Constraints

Federal agencies are under increasing pressure to reduce operating costs. Hiring freezes, early retirements, and limited availability of skilled labor have led to a smaller in-house workforce. As a result, agencies rely more heavily on contractors, often without the tools needed to effectively monitor their performance and ensure that work is completed on time and to standard. This imbalance creates gaps in execution and oversight, allowing maintenance tasks to slip through the cracks.

2. Inefficient and Fragmented Processes

Many agencies still use paper-based workflows or outdated systems that don’t communicate with each other. Work orders may be tracked manually, entered inconsistently, or stored in disconnected databases. These inefficiencies lead to duplication of effort, missed preventive maintenance, and poor visibility into what work has been completed — or not.

3. Poor Data Quality and Lack of Planning Tools

Enterprise Asset Management (EAM) and Computerized Maintenance Management Systems (CMMS) are only as good as the data they contain. Inconsistent data entry, incomplete asset records, and local customizations undermine the reliability of dashboards and KPIs. Without accurate data, agencies struggle to prioritize tasks, forecast needs, and justify funding — all of which contribute to backlog growth.

4. Legacy Processes in Modern Platforms

Agencies often attempt to force legacy workflows into new technology platforms by over-customizing systems like Maximo. This approach leads to complexity, cost overruns, and low user adoption. Instead of leveraging modern capabilities, agencies end up replicating outdated habits, which can slow down progress and perpetuate inefficiencies.

5. Decision-Making Challenges

Backlog decisions are often made reactively. For example, an operations director may defer a roof repair to prioritize HVAC maintenance during summer months or extend the intervals on Preventive Maintenance work for an asset class that has generally been well performing. While these may seem logical in the short term, it can lead to long-term damage and higher costs. Without a structured framework for evaluating asset health, risk, and cost impact, these decisions are made in silos — and the backlog grows.

Section 3: How to Tackle the Backlog Issue

Our recent TRM white paper outlines a roadmap that federal agencies can follow to reduce backlogs and improve O&M efficiency. Several elements in this roadmap directly address the backlog issue:

Build a Clean Data Foundation

Standardizing data formats, eliminating inconsistencies, and defining a single source of truth for assets and contractors is the first step. Clean data enables accurate reporting, better planning, and reliable analytics — all essential for identifying and prioritizing backlog items.

Simplify and Standardize Processes

By eliminating paper-based workflows and aligning processes across locations, agencies can reduce manual work and improve consistency. This makes it easier to track maintenance tasks, identify delays, and escalate critical issues.

Streamline Asset Management System Configurations

Configuring systems like Maximo to support out-of-the-box functionality reduces complexity and improves usability. Role-based dashboards and digital workflows help users manage tasks more efficiently, reducing the likelihood of work being deferred.

Make Analytics Actionable

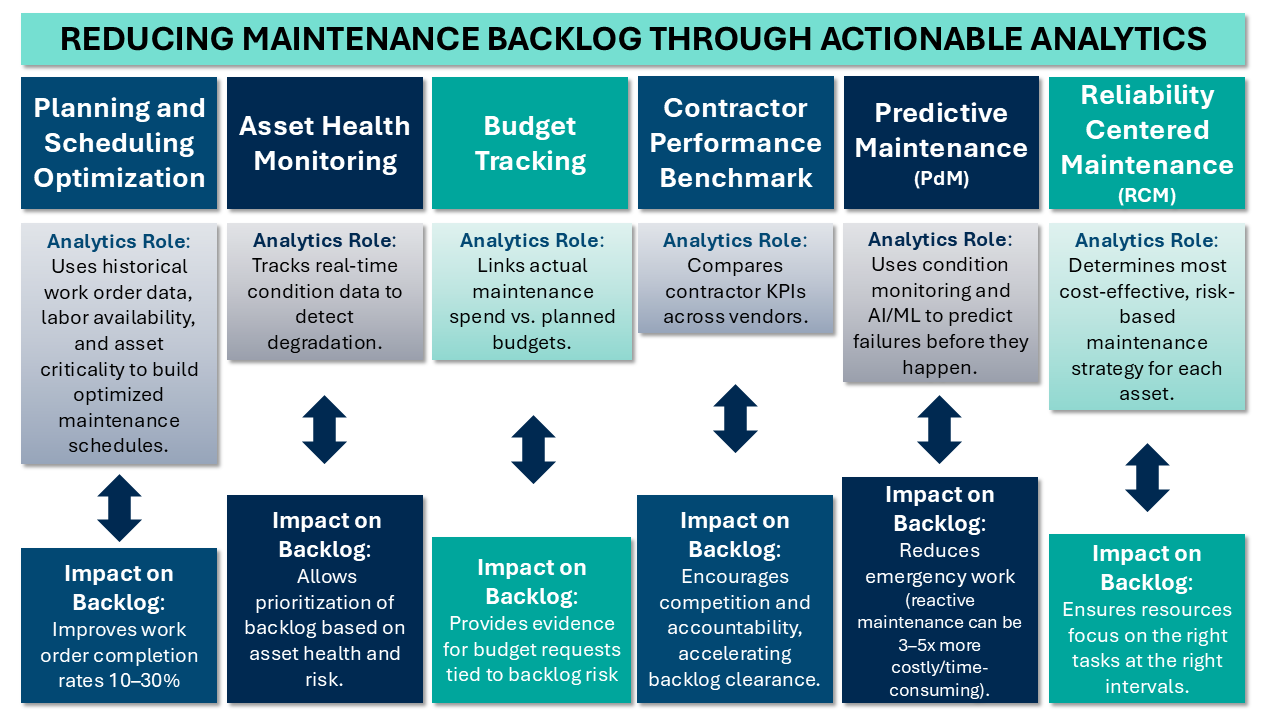

With clean data and standardized processes, agencies can activate advanced analytics in EAM tools. These tools enable:

- Planning and Scheduling optimization

- Asset health monitoring

- Budget tracking

- Contractor performance benchmarking

- Predictive Maintenance (PdM)

- Reliability Centered Maintenance (RCM)

The visibility that these tools create allows agencies to prioritize high-risk assets, better forecast maintenance needs, and allocate resources effectively — all of which help reduce backlog.

Drive Adoption Through Change Management

Technology alone isn’t enough. Agencies must invest in role-based training, in-app guidance and AI-powered support tools to ensure users adopt new workflows. When staff understands the “why” behind the change, they’re more likely to embrace it — leading to better execution and fewer deferred tasks.

How Much Can Backlogs Be Reduced?

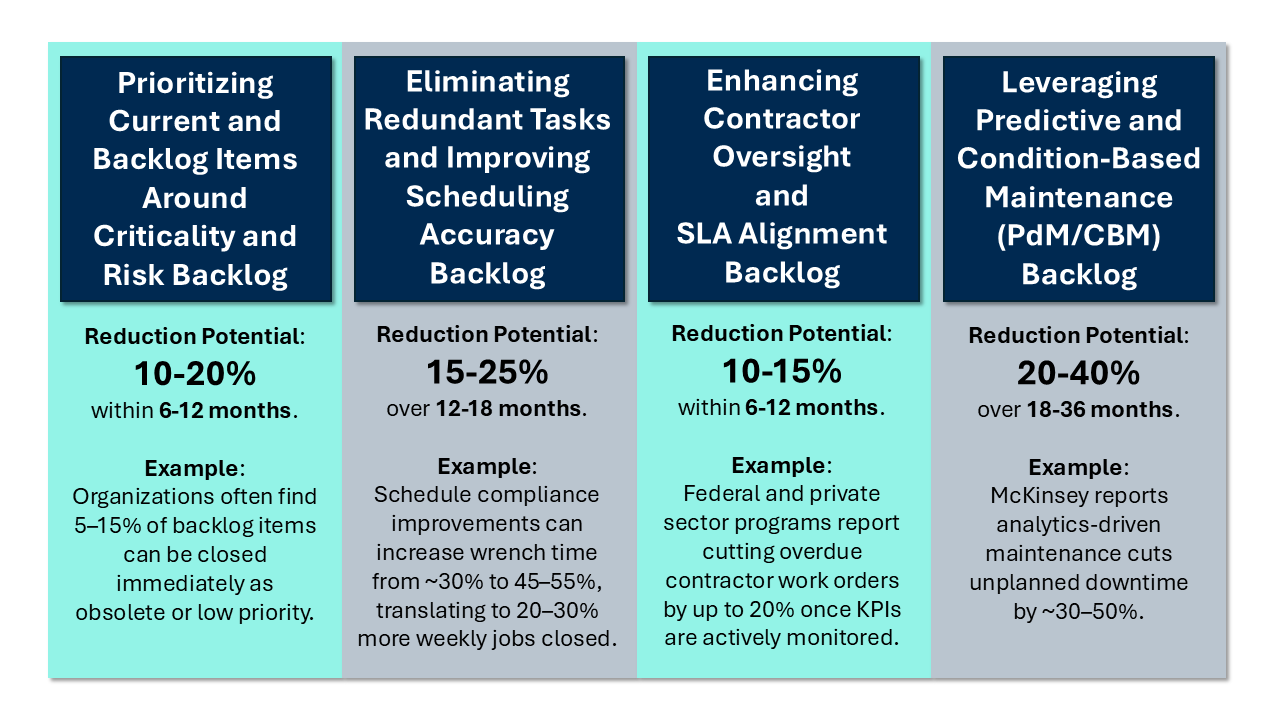

In our experience, organizations that focus on data quality, process standardization, and user adoption can typically reduce their backlog by 20–40% within the first 12–18 months. These improvements come from:

- Prioritizing current and backlog items around criticality and risk

- Eliminating redundant tasks and improving scheduling accuracy

- Enhancing contractor oversight and SLA alignment

- Leveraging predictive and condition-based maintenance technologies

For example, by integrating your EAM with GIS and ERP systems, agencies gain full operational visibility — from asset health to budget planning to execution. This allows for “what-if” scenario modeling, helping leaders make informed decisions about which tasks to defer, escalate, reschedule, or eliminate.

Help Removing your Backlog Risk

Finding ways to proactively manage maintenance programs and reduce the risks associated with deferred work is a critical need in today’s environment. We encourage you to read more in our recent TRM white paper Roadmap for Operations & Maintenance (O&M) Efficiency and Accountability for Federal Agencies as well as encouraging you to contact us and engage our experts. TRM has a 30-year federal track record of empowering agencies to meet their mission in today’s rapidly changing landscape TRM combines decades of federal experience with deep Maximo and CMMS expertise, enabling organizations to achieve operational efficiency.

Contact us at Total Resource Management or email us at askTRM@trmgroup.com.

Explore our LinkedIn page to see how we’re helping organizations solve today’s most complex challenges.

Ready to elevate your asset management?

Connect with TRM to start your journey toward exceptional performance.

Related Resources

Explore insights, guides, and tools designed to help you unlock greater asset management performance and business value.

Unlock smarter

asset management

Ready to elevate your asset management?

Connect with TRM to start your journey toward

exceptional performance.